281-

Latest News

Dec. 2011 -

Jan. 2012 -

Sept. 2012 -

Nov. 2012 -

LTD who will market ISS products in Trinidad.

Jan. 2013 -

April 2013 -

Commercial/Residential Escape Chutes

Escape Chute Systems -

International Safety & Supply is a global Supplier of custom designed escape chute systems

manufactured by Survitec/Risk Safety Systems located in Houston, Texas USA.

Escaping from danger or fire has never been this easy

Escape chutes provide a means of emergency exit that permits rapid, mass evacuation from high rise structures during life threatening emergencies. It is uniquely designed to provide a relatively safe and quick method of vertical or inclined escape and is always accessible and ready for use. it provides a unique solution for vertical escape in sometimes difficult conditions during an emergency evacuation.

A simple Escape System

The construction of the chute helps to protect the evacuees from heat, fire and is used for rescuing the old and the handicapped, it enables unconscious patients and those on stretchers to be brought to safety with very little training. This is sometimes difficult or impossible using traditional rescue equipment.

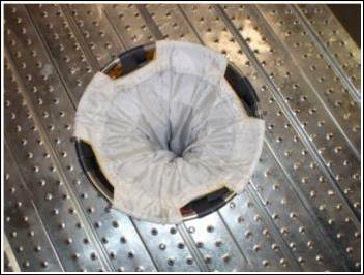

Three way Protection—The escape chute consists of three layers. The outer layer is of a material that will not ignite. The middle layer helps to regulate the speed of decent, inner layer reduces friction.

Commercial and Residential Escape Chute Systems

Multi-

Multi-

Escape Chutes

The escape chute system for multi-

Example of chute calculation:

Assuming a building with 10 storey's inclusive of ground floor (first storey), each storey is of 3 meters high, would need the following length of chute:

• 10 storey minus the highest storey = 9 chute sections.

• 9 chute sections = 8 separate chutes

• Each chute section =3 + 0.35m = 3.35m

• Therefore 8 chute sections =8 x 3.35m =26.80m

• The ground floor chute section = 3 – 0.85m = 2.15m

• Total length for 9 chute sections = 28.95m

9 holes would be required, from the floor of the highest storey to the floor of the

second storey. The multi-

Fire Resistance Door

The entrance at each precinct is protected by fire resistance door of at least RF30 (RF 60 is usually installed). The minimum width of the door is 80cm and the height is 2m.

The door is always closed under normal condition. The doors for the upper floors are open inward and must never pass above the metal ring of the chute frame.

The door for the ground floor is open outward to ease final escape. Anti-

Other Essential Elements:

• Emergency Exit Lights – each floor

• Emergency Lighting – each floor

• Emergency Light -

• Service Lights – each floor

• A set of Rings (iron ring frame, aluminum ring, adjusting rubber profiles) – each floor

• Overpressure air supply system – one unit

• Inter-

• Smoke Hoods – each floor

Integrated System:

When the building is equipped with the emergency power supply (EPS) system, the various

supplementary devices such as over pressurized fan, the inter-

Single Entry Residential Escape Chute

Measurements for custom designed single entry Residential Escape Chute Platform

The single-

The platform can be supplied as a permanent or portable installation. The portable escape chute and container are stored, in the case of an emergency the chute and container are placed into the chute cradle, this a permanent fixture and is located on a window balcony, hand railings or another suitable location, RSS agree position before undertaking of workscope. In all cases design drawings are prepared and issued to the customer for approval.

Buildings vary significantly in terms of:

• Design

• Height

• Size

• Structure

• Construction

RSS would need to know where the proposed location for the single-

• Where would the platform be installed at a rooftop, balcony, window, corridor, etc.?

• What are the building materials at the installation site, tiles, marble, cement, brick, etc?

• Are there any limitations or constraints to the installation area or floor space for the installation of the platform.

• Photos or simple sketches of the installation would be helpful and would greatly assist our design team.

RSS design department work closely with the customer to ensure we have all the necessary measurements of the proposed installation site prior to design.

Correct measurements will save time and money, especially during the installation.

Window Unit Installation:

• Would the platform be installed outside or inside of the window/building?

• The distance between the floor and top of the window parapet.

• The distance between the window and the next window or wall (left and right).

• The distance between the ceiling (wall/floor) and the window.

• The distance between window frame horizontal (inner) when window is open.

• The distance between window frame vertical (inner) when window is open.

• The width/depth of the window parapet wall.

• Is there any decoration outside of the wall (obstruction), the distance between the obstruction and the wall?

• Allowable floor space inside of the window for the platform.

• In which direction the window opens: slide, inward, outward, etc.

• The distance between the window parapet to the ground level minus 80cm.

RSS can design a Escape Chute System to suite your particular needs, please call one of our fully trained representatives

INNER CHUTE / SUPPORT CHUTE

MATERIAL : Polyester

WARP : Polyester

Breaking Tenacity : 185.2 Tensile Strength (Kgf) (C.R.E. Grab Method)

Breaking Tenacity : 82.7 Tearing Strength (Kgf) (C.R.W. Tongue Method)

Flame Resistant : None

Decomposing Temperature : 260 Degrees "C"

WEFT : Polyester

Breaking Tenacity : 184.9 Tensile Strength (Kgf) (C.R.E. Grab Method)

Breaking Tenacity : 80.4 Tearing Strength (Kgf) (C.R.W. Tongue Method)

Flame Resistant : None

Decomposing Temperature : 260 Degrees "C"

OUTER CHUTE / FLAMEPROOF CHUTE

MATERIAL : Electro Glass, Fiber Glass (Gray / Silver)

Weight : 440g/m2

Softening Point : 800 Degrees "C"

Temperature Limit for Continual use : 550 to 600 Degrees "C"

Tensile Strength -

Tensile Strength -

Escape Chute Weight : 2.61 Kgs Per Liner Meter

MIDDLE / BREAKING CHUTE

MATERIAL : Nylon 1901

WARP : Nylon 1901

Breaking Tenacity : 52.0 Tensile Strength (Kgf) (C.R.E. Grab Method)

Breaking Tenacity : 3.0 Tearing Strength (Kgf) (C.R.W. Tongue Method)

Flame Resistant : None

Decomposing Temperature : 215 Degrees "C"

WEFT : Nylon 1901

Breaking Tenacity : 51.9 Tensile Strength (Kgf) (C.R.E. Grab Method)

Breaking Tenacity : 2.8 Tearing Strength (Kgf) (C.R.W. Tongue Method)

Flame Resistant : None

Decomposing Temperature : 215 Degrees "C"

MATERIAL : Stainless Steel Springs AIS 1304

Breaking Tenacity : 150 Kgf/mm2 (1471N/mm2)

ADDITIONAL TYPES OF ESCAPE CHUTES AVAILABLE

1. IESC Integrated Escape Chute System

2. Derrickman Vertical Escape System

3. TEMPSC Davit Launch Escape System

4. MAS-

5. Fire Department Escape Chute System

International Safety & Supply -

For a Quotation Please Contact us at: info@internationalsafetysupply.com or call

281-