281-

Latest News

Dec. 2011 -

Jan. 2012 -

Sept. 2012 -

Nov. 2012 -

LTD who will market ISS products in Trinidad.

Jan. 2013 -

April 2013 -

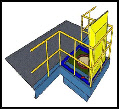

Derrickman Escape Chute

Escape Chute Systems -

International Safety & Supply is a global Supplier of custom designed escape chute systems

manufactured by Survitec/Risk Safety Systems located in Houston, Texas USA.

Escaping from danger or fire has never been this easy

Escape chutes provide a means of emergency exit that permits rapid, mass evacuation from derrick structures during life threatening emergencies. It is uniquely designed to provide a relatively safe and quick method of vertical or inclined escape and is always accessible and ready for use. it provides a unique solution for vertical escape in sometimes difficult conditions during an emergency evacuation.

A simple Escape System

The construction of the chute helps to protect the evacuees from heat and fire and is used to deliver evacuees to safety with very little training. This is sometimes difficult or impossible using traditional rescue equipment.

Three way Protection—The escape chute consists of three layers. The outer layer is of a material that will not ignite. The middle layer helps to regulate the speed of decent, inner layer reduces friction.

Offshore &Onshore Derrickman Escape Chute Systems

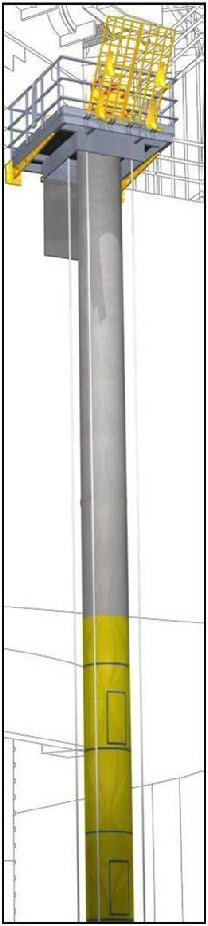

Provides rapid vertical evacuation from Derrick Towers in an emergency situation.

Totally enclosed and offering heat protection from radiated heat flux. The RSSDM10 Vertical Three Layered Escape Chute is a rapid and safe method of evacuating from heights to deck level.

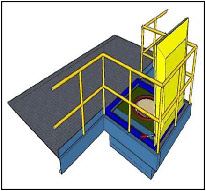

Supplied with a purpose built support frame the chute system and frame comprises

of the following:-

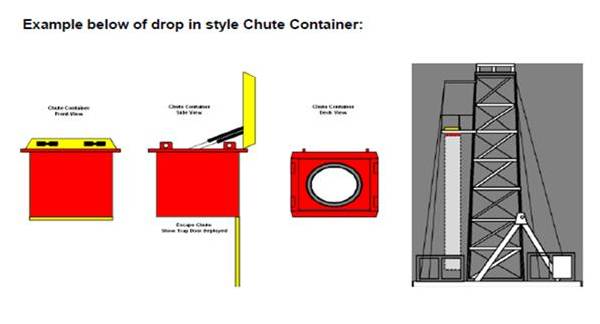

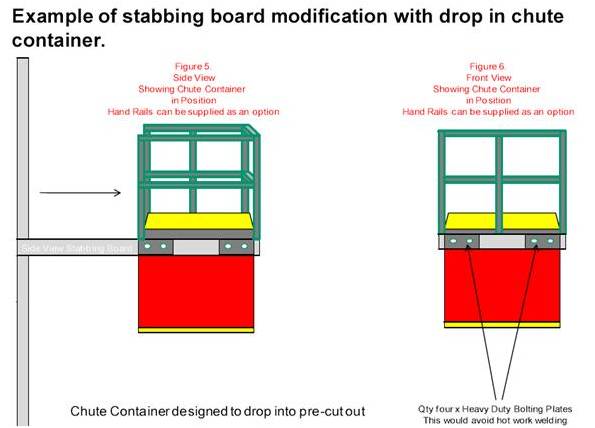

Box section epoxy painted frame designed to accommodate the drop in chute container

Set of Safety Handrails and Access Gate – Optional

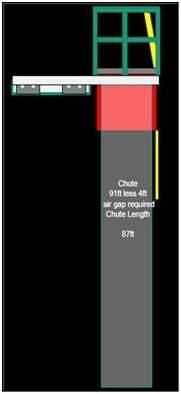

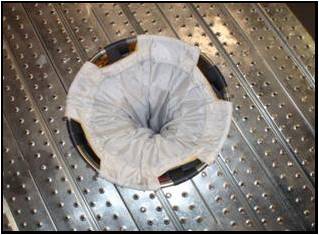

Three Layered Vertical Escape Chute designed to support a dead weight of 2 – ton and heat resistant to 600 degrees and melting point of 800 degrees. Chute length varies dependent on application, however in all cases a 1 x meter air gap is required for evacuees to exit.

Light weight chute container with lower trap door and hinged lid, hydraulic dampened arms, based on 115ft of escape chute. The chute container would need to be 56” in height excluding the lid.

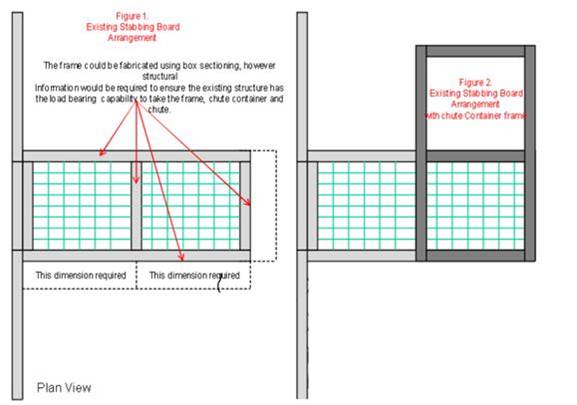

Width and depth is yet to be determined, but the minimum width requirement is 29” as the chute aperture is 25” and 2” required on all sides of the chute hole for support.

In all cases design criteria is agreed with the customer and drawings issued for approval prior to manufacturing.

The system can be supplied with purpose built safety handrails and access gate, deployment mechanism and chute container.

Technical, Testing and Individual Component Certification, Training and Manuals:

In all cases full testing is carried out ensuring that the escape chute system performs correctly, All components will be supplied with certification, covering: Escape Chute, frame Assembly and Mechanical Deployment device.

Full operational and maintenance manuals are supplied in electronic and paper format. Full onsite training can be provided. Risk Safety Systems can also provide Train the Trainer courses whereby key personnel are trained to become certified trainers.

Train the Trainer courses can be carried out at the customer’s facility or at a certified RSS training facility.

Each candidate is certified for a period of 2 years with certificates issued. The

trainers then provide on-

Annual Servicing of the ECS:

Annual inspection of the RSSDM-

The annual inspection includes testing and re-

The RSSDM-

On the 5th year a complete inspection is carried out and the escape chute removed, unpacked, with a full inspection carried out.

RSS can also provide onsite support for installation and fitting if the customer decides to carry out the installation. If required RSS can also provide a survey prior to manufacture and installation to ensure that the proposed design is structurally suitable for proposed application.

Example of stabbing board modification as a side mounted evacuation point was required with this application

INNER CHUTE / SUPPORT CHUTE

MATERIAL : Polyester

WARP : Polyester

Breaking Tenacity : 185.2 Tensile Strength (Kgf) (C.R.E. Grab Method)

Breaking Tenacity : 82.7 Tearing Strength (Kgf) (C.R.W. Tongue Method)

Flame Resistant : None

Decomposing Temperature : 260 Degrees "C"

WEFT : Polyester

Breaking Tenacity : 184.9 Tensile Strength (Kgf) (C.R.E. Grab Method)

Breaking Tenacity : 80.4 Tearing Strength (Kgf) (C.R.W. Tongue Method)

Flame Resistant : None

Decomposing Temperature : 260 Degrees "C"

OUTER CHUTE / FLAMEPROOF CHUTE

MATERIAL : Electro Glass, Fiber Glass (Gray / Silver)

Weight : 440g/m2

Softening Point : 800 Degrees "C"

Temperature Limit for Continual use : 550 to 600 Degrees "C"

Tensile Strength -

Tensile Strength -

Escape Chute Weight : 2.61 Kgs Per Liner Meter

MIDDLE / BREAKING CHUTE

MATERIAL : Nylon 1901

WARP : Nylon 1901

Breaking Tenacity : 52.0 Tensile Strength (Kgf) (C.R.E. Grab Method)

Breaking Tenacity : 3.0 Tearing Strength (Kgf) (C.R.W. Tongue Method)

Flame Resistant : None

Decomposing Temperature : 215 Degrees "C"

WEFT : Nylon 1901

Breaking Tenacity : 51.9 Tensile Strength (Kgf) (C.R.E. Grab Method)

Breaking Tenacity : 2.8 Tearing Strength (Kgf) (C.R.W. Tongue Method)

Flame Resistant : None

Decomposing Temperature : 215 Degrees "C"

MATERIAL : Stainless Steel Springs AIS 1304

Breaking Tenacity : 150 Kgf/mm2 (1471N/mm2)

ADDITIONAL TYPES OF ESCAPE CHUTES AVAILABLE

1. IECS Integrated Escape Chute System

2. TEMPSC Davit launch Escape System

3. MAS-

4. Fire Department Escape Chute System

5. Commercial & Residential Escape Chute System

International Safety & Supply -

For Quotation Please Contact us at: info@internationalsafetysupply.com or call 281-