281-

Latest News

Dec. 2011 -

Jan. 2012 -

Sept. 2012 -

Nov. 2012 -

LTD who will market ISS products in Trinidad.

Jan. 2013 -

April 2013 -

Davit Launched Escape Chute

Escape Chute Systems -

International Safety & Supply is a global Supplier of custom designed escape chute systems

manufactured by Survitec/Risk Safety Systems located in Houston, Texas USA.

Escaping from danger or fire has never been this easy

Escape chutes provide a means of emergency exit that permits rapid, mass evacuation from offshore installations during life threatening emergencies. It is uniquely designed to provide a relatively safe and quick method of vertical escape and is always accessible and ready for use. it provides a unique solution for vertical escape in sometimes difficult conditions during an emergency evacuation.

A simple Escape System

The construction of the chute helps to protect the evacuees from heat and fire and is used to deliver evacuees to safety with very little training. This is sometimes difficult or impossible using traditional rescue equipment.

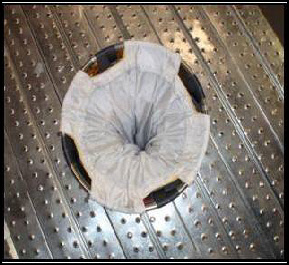

Three way Protection—The escape chute consists of three layers. The outer layer is of a material that will not ignite. The middle layer helps to regulate the speed of decent, inner layer reduces friction.

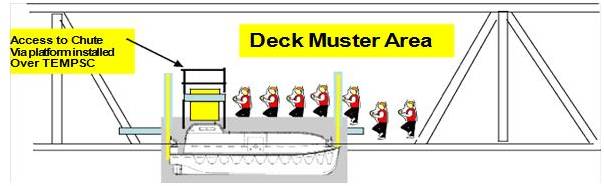

Vertical Escape Chute System for TEMPSC Davit Launch

TEMPSC Modification -

Utilizing a Vertical Three Layer Escape Chute System

Executive Summary.

Totally Enclosed Mechanically Propelled Survival Craft (TEMPSC), more generally referred to as Lifeboats are available in a variety of craft types; with a variety of release gear types, engines and, davit/winch types.

They are boarded at deck level and once fully loaded the vessel is then lowered to sea on davits or dropped free fall from a cradle. In either case the personnel are required to embark and be seated prior to and during the launch process.

They are widely utilized by the offshore oil & gas industry as the primary means

of evacuation from a facility when Helicopter evacuation is not available. However,

as early as October 1986 (within months of their use becoming mandatory in UK), UK

regulators had become concerned at the number of reported accidents involving davit

launched TEMPSC on-

As a result UK Department of Trade (DOT) issued an M.1248 notice reminding those involved in lifeboat drills & tests of the need for full and regular training in the correct use of the equipment.

Since that time and despite regular warnings from flag state administrations, underwriters and classification societies the number of accidents and seriousness of the consequences has continued to rise. This has lead to a number of studies into Life boat safety.

These include:

OCIMF – Results of a Survey into Life Boat Safety (Ref 2).

OCIMF – Intertank & SIGTTO – Life Boat Incident Survey 2000 (Ref 3 & 4).

MAIB – Review of Life Boat and Launching Systems Accidents (Ref 5).

As a result the need for a system that would enable the TEMPSC to be launched and then boarded was identified.

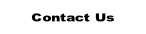

This paper sets forth a scheme for an Alternative Embarkation System for Davit Launched TEMPSC that allows the TEMPSC to be launched with minimal/no manning; allowing the crew to embark once the TEMPSC is safely deployed to sea level.

This document is supported by drawings, calculations and other supporting data which are the intellectual property of Risk Safety Systems Inc. The proposed embarkation scheme is described in summary below:

In evaluating possible options for the reduction of risks posed to personnel evacuating from an offshore facility using a Davit Launched TEMPSC it became obvious from the data derived from various studies referenced within this document that there existed a primary risk driver.

That was, the need for personnel to board the TEMPSC at its stowed location at various

deck levels all of which required the TEMPSC to be lowered fully manned 30-

Therefore, attention was given to reducing personnel exposure to the risks associated with lowering the TEMPSC to sea while manned. In order to significantly reduce the risks associated with the use of a davit launched TEMPSC during an evacuation it is necessary to minimize the exposure of the crew to the risks associated with lowering the TEMPSC fully manned.

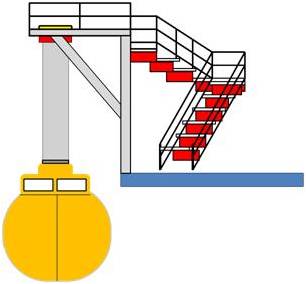

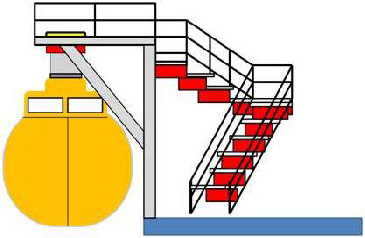

The implied solution is to modify the process such that the TEMPSC can be launched and the crew board once the TEMPSC is at a safe height location at or slightly above sea level.

This removes the risk of the TEMPSC falling to sea fully loaded likely resulting in fatality or injury to the crew.

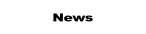

On that basis RSS propose that a stand alone lightweight access system be installed such that it locates a vertical escape chute over the rear top access hatch to the TEMPSC. Figures 1.1 and 1.2 illustrate the system installed over an existing TEMPSC station. As can be seen the system does not interfere with access for maintenance or launch of the TEMPSC or Davits.

As can be seen the proposed system is simple, low weight, low cost and based on RSS existing tried and tested vertical escape chute technology. The system can be installed with TEMPSC in place with minimal interference to facility as no hot work is required (platform is bolted into position).

In conclusion, the RSS TEMPSC Embarkation System offers a significantly reduced risk to personnel requiring evacuation from a facility via davit launched TEMPSC for the following reasons:

It eliminates risk to personnel of falling to sea in fully loaded TEMPSC should Davit or other system fail. This implies a significant potential reduction in IRPA, PLL or FAR for offshore facilities while not imposing significant additional costs (cost beneficial).

It removes personnel from hazards at topsides enabling them to wait in the TEMPSC at or near sea level while any final personnel missing from muster are being located. This eliminates exposure to heat flux, flame or contamination of TEMPSC environment by combustion products which may be more likely to occur if the TEMPSC is boarded and loaded at deck level.

The system can be retrofitted with no significant impact on facility operations or use of current evacuation systems.

The system is low cost and lightweight with low maintenance.

Personnel boarding time is not increased significantly by using the vertical escape chute.

INNER CHUTE / SUPPORT CHUTE

MATERIAL : Polyester

WARP : Polyester

Breaking Tenacity : 185.2 Tensile Strength (Kgf) (C.R.E. Grab Method)

Breaking Tenacity : 82.7 Tearing Strength (Kgf) (C.R.W. Tongue Method)

Flame Resistant : None

Decomposing Temperature : 260 Degrees "C"

WEFT : Polyester

Breaking Tenacity : 184.9 Tensile Strength (Kgf) (C.R.E. Grab Method)

Breaking Tenacity : 80.4 Tearing Strength (Kgf) (C.R.W. Tongue Method)

Flame Resistant : None

Decomposing Temperature : 260 Degrees "C"

OUTER CHUTE / FLAMEPROOF CHUTE

MATERIAL : Electro Glass, Fiber Glass (Gray / Silver)

Weight : 440g/m2

Softening Point : 800 Degrees "C"

Temperature Limit for Continual use : 550 to 600 Degrees "C"

Tensile Strength -

Tensile Strength -

Escape Chute Weight : 2.61 Kgs Per Liner Meter

MIDDLE / BREAKING CHUTE

MATERIAL : Nylon 1901

WARP : Nylon 1901

Breaking Tenacity : 52.0 Tensile Strength (Kgf) (C.R.E. Grab Method)

Breaking Tenacity : 3.0 Tearing Strength (Kgf) (C.R.W. Tongue Method)

Flame Resistant : None

Decomposing Temperature : 215 Degrees "C"

WEFT : Nylon 1901

Breaking Tenacity : 51.9 Tensile Strength (Kgf) (C.R.E. Grab Method)

Breaking Tenacity : 2.8 Tearing Strength (Kgf) (C.R.W. Tongue Method)

Flame Resistant : None

Decomposing Temperature : 215 Degrees "C"

MATERIAL : Stainless Steel Springs AIS 1304

Breaking Tenacity : 150 Kgf/mm2 (1471N/mm2)

ADDITIONAL TYPES OF ESCAPE CHUTES AVAILABLE

1. IECS Integrated Escape Chute System

2. Derrickman Vertical Escape System

3. MAS-

4. Fire Department Escape Chute System

5. Commercial & Residential Escape Chute System

International Safety & Supply -

For Quotation Please Contact us at: info@internationalsafetysupply.com or call 281-