281-

Latest News

Dec. 2011 -

Jan. 2012 -

Sept. 2012 -

Nov. 2012 -

LTD who will market ISS products in Trinidad.

Jan. 2013 -

April 2013 -

MAS-

Escape Chute Systems -

International Safety & Supply is a global Supplier of custom designed escape chute systems

manufactured by Survitec/Risk Safety Systems located in Houston, Texas USA.

Escaping from danger or fire has never been this easy

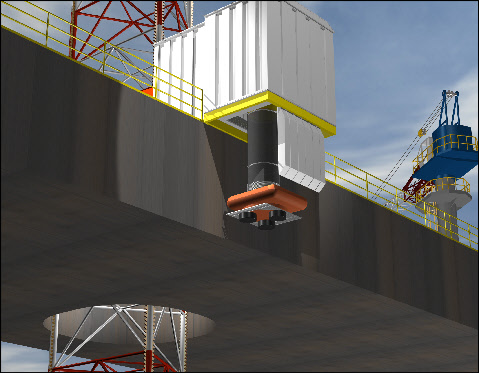

Escape chutes provide a means of emergency exit that permits rapid, mass evacuation from offshore installations during life threatening emergencies. It is uniquely designed to provide a relatively safe and quick method of escape and is always accessible and ready for use. It provides a unique solution for vertical escape in sometimes difficult conditions during an emergency evacuation.

A simple Escape System

The construction of the chute helps to protect the evacuees from heat and fire and is used to deliver evacuees to safety with very little training. This is sometimes difficult or impossible using traditional rescue equipment.

MAS-

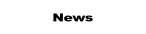

The MAS-

The MAS-

The MAS-

MAS-

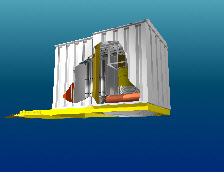

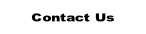

. Bolt down Skid Frame with over-

· Skid frame mounted container with rear door access and hazard resistant outer cladding as standard

· Internal structural support frame bolted to the container supporting pneumatic winch, cables & pulley system & escape chute

· Internal Explosion proof lighting system rated for hazardous area (Classification

Zone I Div 1 Class I) and three hour emergency back-

· Pneumatic winch with pneumatic accumulators with capacity as necessary,

· Three wire cable and pulley system connected to the winch drum and terminating at the tensioning cans

· Vertical Kevlar zig-

· High capacity 100 person SOLAS (A) pack approved life raft with integrated buoyant breakaway landing

platform configurable to enable the life raft to freely rotate around the chute column by means of a hoop/bearing assembly

· Open grid lightweight support frame for storing the life raft in the stowed condition

· Cable tensioning cans to hold the deployed system in the vertical position

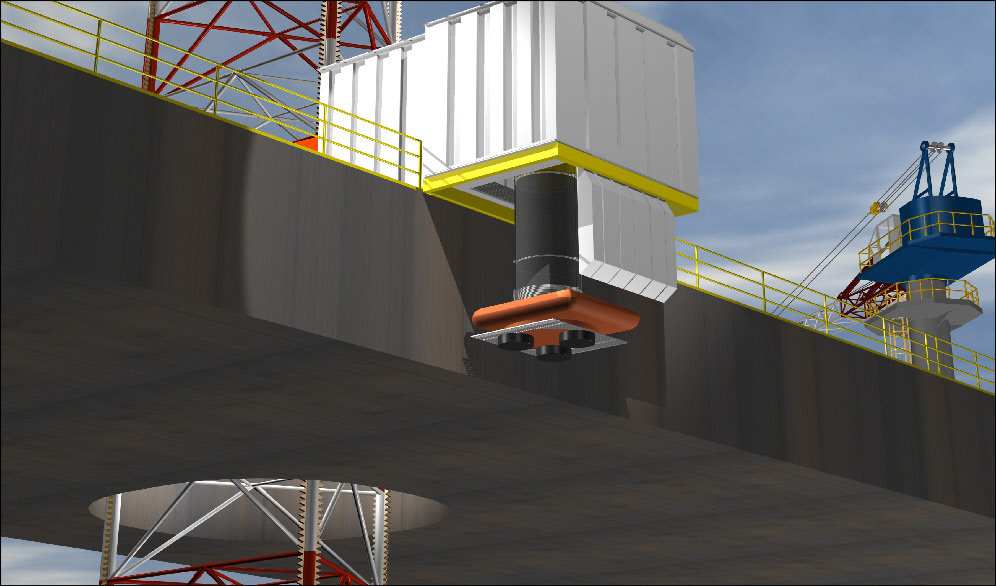

Cantilever Skid Frame:

The cantilever skid frame is fabricated from 12” x 5” x ½” (305 mm x 125 mm x 12.7mm)

box section A36 grade carbon steel. The rear section of the cantilever skid frame

is constructed in such a way that it can be bolted to the existing facility deck

by the use of 1” diameter high tensile steel nuts and bolts. The rear section incorporates

a checkered pattern floor decking, providing the main floor for the MAS-

System Container Rear (aft) Section:

The MAS-

The main containment system is designed to be blast resistant rated to 5psi @ 200msec impulse duration. Blast testing was undertaken by the container manufacturer utilizing 1250Ib of high explosives ANFO at a standoff distance of 33.5m (110ft).

The AFT container specifications are as follows:

. Aft BP container size: 2.44m(L) x 2.44m(W) x 3.05m(H) -

· Electrical System – Zone 1. Class1. Div1. ATEX Approved

· Emersion Rating for Electrical Components Min – IP66

· Internal Lighting System ATEX with three hour battery back-

· ATEX approved pneumatic deployment/retrieval winch accumulator bank

· API 753 Compliant

· ASCE Medium Response 5/8/10/PSI

· Red or White exterior paint 3 coat epoxy with rubberized roof coating suitable for marine applications.

· Steel reinforced corrugated wall and roof panels

System Container Forward (Deployment) Section:

The MAS-

The fwd container houses the life raft, escape chute, GRP storage frame, and the tensioning cans. The trap door deployment handles are located at floor level as you enter the fwd section. The life raft can be sized according to the facilities requirements; typical life raft sizing is 50, 100 and 150 man capacity.

The FWD container specifications are as follows:

. FWD BP container size: 3.36m(L) x 2.44m(W) x 3.05m(H) -

· Internal Lighting System ATEX with three hour battery back-

· API 753 Compliant

· ASCE Medium Response 5/8/10/PSI

· Red or White exterior paint 3 coat epoxy with rubberized roof coating suitable for marine applications.

· Steel reinforced corrugated wall and roof panels

V450 Kevlar Variable Height Telescoping Chute

System utilizes the ECS RSS-

The RSS Kevlar Escape chute provides heat flux protection of 650 degree, however the chute is netted and can still allow heat to penetrate through the tightly knitted holes, therefore Risk Safety Systems also supply an additional outer layer that is fully enclosed providing, true 650 degree heat protection and a melting point of 800 degrees C’. This outer layer is fitted to the maximum ballast level or highest recorded swell and is designed to provide maximum heat flux protection at deck levels.

Each chute section has a 1.22m (48”) Kevlar slide fitted. The slides are opposing

on each 1.22m (48”) cell section and provide a zig zag effect. Each 1.22m (48”)

chute section has an access compartment for egress to the self-

Three steel braided winch wires are connected to the winch located in the aft container at deck level and are attached at each 1.22m (48”) section of the chute column and terminated at the life raft breakaway plate. Upon deployment the chute, raft and tensioning cans are lowered to sea level using the pneumatic winch.

External Electro Fiberglass Outer Sleeve:

The V450 Kevlar netted escape chute is supplied with 650°C heat protection and melting

point of 800°C. Although the micro-

The Electro-

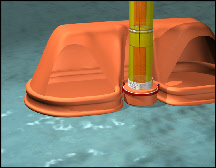

High Capacity Life Raft with Breakaway Landing Platform:

The life raft is a modified Zodiac SOLAS (A) pack raft size 100 person, verifying

life-

The breakaway platform includes a patented slip ring counter rotating bearing arrangement allowing the raft to rotate freely in the X,Y & Z planes around the boarding platform under the influence of wind and current in evacuation conditions. This is most desirable and a patented innovation as previous technology has only enabled the raft to move in the single vertical plane under the influence of wave action.

System Tensioning Cans:

The tensioning cans are intended to sit in the water under the debarkation raft suspended at the end of the three main steel winch cables. Their function is to provide stability to the chute column and hold the chute in the vertical position. They designed in conformance with LSA Code 2010 to hold the chute column within 15o of vertical for a wind speed of Beaufort 6 with a significant wave height of 3m (10ft). Calculations are supplied to confirm correct tensioning cans weight/ mass to meet these requirements. Where client requirements vary the tensioning cans can be sized accordingly.

Certification & Conformance:

•All RSS offshore evacuation systems are designed to comply with IMO/LSA 2010 edition.

•DNV 3rd party inspection can be provided during the manufacturing process.

•Compliance with the requirements of NORSOK can be provided and witnessed by DNV as verification of conformance.

•The MAS-

Train the Trainer Program: RSSUS has included the provision to supply Train the Trainer

courses whereby the customer’s key personnel are trained to become certified trainers.

The Train the Trainer courses can be carried out at one of our training facilities,

or on site. The Train the Trainer program requires a morning classroom session and

actual training using the training chute Upon completion and satisfactory training

the Trainer becomes certified and issued with a two year certificate. He/she in turn

trains on-

MAS-

Escape Chute System

View an Animated Video of Gravity Escape Chute Deployment →

IECS OPERATING & TRAINING MODULES

In an emergency where personnel are required to evacuate using the IECS the following procedure should be followed: Assemble at the IECS muster station. Persons designated Topsides Chute Access Supervisor (TCAS), Debarkation Raft Supervisor (DRS), Life Raft 1 & 2 Access Supervisors (LRAS) commence duties

ADDITIONAL TYPES OF ESCAPE CHUTES AVAILABLE

1. IECS Integrated Escape Chute System

2. Offshore & Onshore Derrickman Escape Chute System

3. TEMPSC Davit launch Escape System

4. Fire Department Escape Chute System

5. Commercial & Residential Escape Chute System

International Safety & Supply -

For a Quotation Contact us at: info@internationalsafetysupply.com or call 281-