281-

Latest News

Dec. 2011 -

Jan. 2012 -

Sept. 2012 -

Nov. 2012 -

LTD who will market ISS products in Trinidad.

Jan. 2013 -

April 2013 -

Fire Department Escape Chutes

Escape Chute Systems -

International Safety & Supply is a global Supplier of custom designed escape chute systems

manufactured by Survitec/Risk Safety Systems located in Houston, Texas USA.

Escaping from danger or fire has never been this easy

Escape chutes provide a means of emergency exit that permits rapid, mass evacuation from high rise structures during life threatening emergencies. It is uniquely designed to provide a relatively safe and quick method of vertical or inclined escape and is always accessible and ready for use. it provides a unique solution for vertical escape in sometimes difficult conditions during an emergency evacuation.

A simple Escape System

The construction of the chute helps to protect the evacuees from heat, fire and is used for rescuing the old and the handicapped, it enables unconscious patients and those on stretchers to be brought to safety with very little training. This is sometimes difficult or impossible using traditional rescue equipment.

Three way Protection—The escape chute consists of three layers. The outer layer is of a material that will not ignite. The middle layer helps to regulate the speed of decent, inner layer reduces friction.

Fire Department Escape Chute Systems

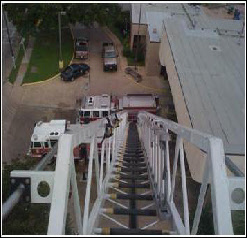

Mounting on the Bucket of Ladder and Tower Trucks

Portable Vertical Escape Chute System for Mounting on bucket of Ladder and Tower Trucks.

The quick deployment of the mobile rescue unit provides people who are trapped buildings

a safer means of rapid escape from the bucket to ground and reduces the risk of exposure

for the firefighters. This approach eliminates the time involved in lowering and

raising the aerial-

Should the surroundings of the building not be accessible by the fire aerial truck, the portability of the unit allows the rescue personnel to carry the unit to each desired floor. This additional equipment allows the rescue chute to be positioned at the parapet of the balcony or window. However, the rescuer must ensure that the wall of the balcony and window, ceiling and floor are structurally safe for the unit to be deployed. The maximum safety load is 200 kg or 50 meter in height.

PORTABLE ESCAPE:

Fire & Rescue & Emergency Services

Escape Chutes can be fitted to Fire Department Aerial Ladders and Snorkel Platforms, this will increase the rate at which evacuees can be evacuated from a high rise building, thus reducing the risk of exposure of the fireman.

The movable/portable chute has become standard rescue equipment used by fire bridges worldwide for high rise rescue operations. With additional equipment, the portable platform can also be mounted on the parapet of the balcony and window.

The chute is constructed of 3 layers, the outer layer is fire resistant-

Protection, the evacuees are protected once inside the chute from flames, heat, and smoke.

RSS ESCAPE CHUTE Technical Specifications for the Mobile/Portable Rescue Chute.

Mobile/Portable Rescue Chutes have become standard rescue equipment for fire aerial ladder trucks such as Bronto Skylift, Simon Snorkel, Cella, Iveco Magirus, Metz and Rosenbauer and are used by fire brigades worldwide for high rise rescue operations.

Characteristic Features

The Mobile Unit provides a dual function in one, portable and suitable for the rescue of people trapped in tall buildings.

The universal standard foldable platform is portable and adaptable for use with mobile rescue units, such as the fire brigades’ aerial ladder trucks. The foldable platform can either be ready mounted on the bucket or in a cassette, which is ready for use as required. With additional equipment, this platform can also be used from the window or balcony of a structure.

The chute main body is made up of several segments of 3 layers chute. The start piece of the first segment, usually of 61m or 8 long with fire snap hooks on one end.

The other segment of chute with fire snap hooks on both ends usually corresponds to the height of a regular floor. The starting piece and the other segments are easily connected with fire snap hooks for extending the chutes height to meet the desired chute length. Customers can specify the length for the start piece or each segment to meet their individual rescue needs.

Material Specifications

Universal foldable platform – 100% aluminum (frame and cast), foldable, portable, attachable to buckets of most fire trucks. Aluminum cast Alsi nr 6. Steel ring. Portable carrier bags are provided for the storage of each chute section.

The chute main body material is Gray in color, constructed of three layers chute.

This 3-

Outer Chute – The protection layer with a heat resistance of 600 degrees and a melting

point of 800 degrees. Temperature limits for continuous use 550-

This material provides a shield from flame, and provides protection to the two underlying chutes.

Middle Chute – The braking layer Modacryl and Elastomer (lycra) at softening point of 165 degree Celsius. This elastic material, covering inner chute that enables the user to control his/her speed of descent. The important properties of these materials are its modulus of elasticity (260%) and its withstanding temperatures of 165 degrees Celsius.

Inner Chute – The friction layer Interlayer Para Aramid, warp and vet Viyl Chloride fibers. Strength ISO 5081 (N) 3482 stripes 50mm and its tensile strength ISO (N) 10mm stripes support the chute. No softening point, decomposing temperature at about 500 degree Celsius. Evacuees slide down the chute through this inner layer, which bears the tensile stress, and has extremely low friction to minimize friction burns or chafing.

Each fire snap hook is constructed from stainless steel, these can be adjusted to extend or shorten the chute length. Each end of lengthening joint contains 1 segment of chute consisting of 12 sets of fire snap hooks for connection to the next segment of chute.

Descent and Safety

The system works on the principle of gravity, using the stress and friction of the body as it slides through the chute. Usability for all people, regardless of body size, shape and weight, injured on a stretcher or unconscious people can use the chute. Once inside the chute the evacuee will arrive at ground level quickly and relatively safely.

For conscious evacuees, slide down the chute and push out your elbows or knees. For a more rapid descent, the users keep their body as straight as possible. No other method of evacuation allows for such flexibility in control of descent speed: average speed for evacuee with right behavior is about 2.5 m per second, which may vary from 0 – 5 m per second. It would take approximately 35 – 40 seconds to descend a chute of up to 50 meters and capable of conveying up to 30 persons per minute from any storey to safety.

For safety reasons, the SOP requires a helper at ground level to control a fast descend and guide the user out of the chute. By twisting and slowly untwisting the chute you can control the speed of a descending person. This method enables the injured, unconscious, disabled and small children to be evacuated safely.

Storage of Chute:

The chutes are folded inside its protective container and portable bag(s), providing

year round weather protection, these chutes are then ready for use at any time. After

use, the chute can be re-

INNER CHUTE / SUPPORT CHUTE

MATERIAL : Polyester

WARP : Polyester

Breaking Tenacity : 185.2 Tensile Strength (Kgf) (C.R.E. Grab Method)

Breaking Tenacity : 82.7 Tearing Strength (Kgf) (C.R.W. Tongue Method)

Flame Resistant : None

Decomposing Temperature : 260 Degrees "C"

WEFT : Polyester

Breaking Tenacity : 184.9 Tensile Strength (Kgf) (C.R.E. Grab Method)

Breaking Tenacity : 80.4 Tearing Strength (Kgf) (C.R.W. Tongue Method)

Flame Resistant : None

Decomposing Temperature : 260 Degrees "C"

OUTER CHUTE / FLAMEPROOF CHUTE

MATERIAL : Electro Glass, Fiber Glass (Gray / Silver)

Weight : 440g/m2

Softening Point : 800 Degrees "C"

Temperature Limit for Continual use : 550 to 600 Degrees "C"

Tensile Strength -

Tensile Strength -

Escape Chute Weight : 2.61 Kgs Per Liner Meter

MIDDLE / BREAKING CHUTE

MATERIAL : Nylon 1901

WARP : Nylon 1901

Breaking Tenacity : 52.0 Tensile Strength (Kgf) (C.R.E. Grab Method)

Breaking Tenacity : 3.0 Tearing Strength (Kgf) (C.R.W. Tongue Method)

Flame Resistant : None

Decomposing Temperature : 215 Degrees "C"

WEFT : Nylon 1901

Breaking Tenacity : 51.9 Tensile Strength (Kgf) (C.R.E. Grab Method)

Breaking Tenacity : 2.8 Tearing Strength (Kgf) (C.R.W. Tongue Method)

Flame Resistant : None

Decomposing Temperature : 215 Degrees "C"

MATERIAL : Stainless Steel Springs AIS 1304

Breaking Tenacity : 150 Kgf/mm2 (1471N/mm2)

ADDITIONAL TYPES OF ESCAPE CHUTES AVAILABLE

1. IESC Integrated Escape Chute System

2. Derrickman Vertical Escape System

3. TEMPSC Davit Launch Escape System

4. MAS-

5. Commercial & Residential Escape Chute System

International Safety & Supply -

For a Quotation Please Contact us at: info@internationalsafetysupply.com or call

281-