281-

Latest News

Dec. 2011 -

Jan. 2012 -

Sept. 2012 -

Nov. 2012 -

LTD who will market ISS products in Trinidad.

Jan. 2013 -

April 2013 -

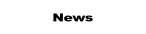

Escape Chute Systems

Escape Chute Systems

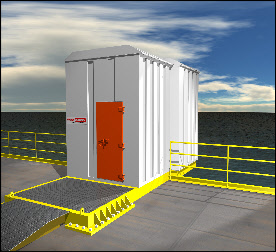

International Safety & Supply is a global Supplier of custom designed escape chute systems

manufactured by Survitec /Risk Safety Systems located in Houston, Texas USA.

Escaping from danger or fire has never been this easy

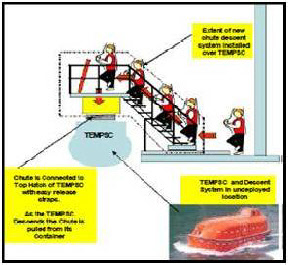

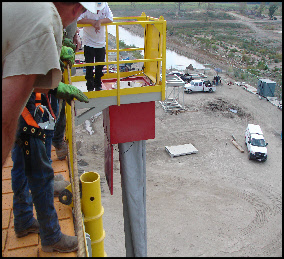

Escape chutes provide a means of emergency exit that permits rapid, mass evacuation from structures during life threatening emergencies. It is uniquely designed to provide a relatively safe and quick method of vertical escape and is always accessible and ready for use. it provides a unique solution for vertical escape in sometimes difficult conditions during an emergency evacuation.

A simple Escape System

The construction of the chute helps to protect the evacuees from heat and fire and allows evacuees to be brought to safety with very little training. This is sometimes difficult or impossible using traditional rescue equipment.

For a Quotation Contact: us at:: Info@internationalsafetysupply.com or call:

281-

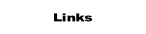

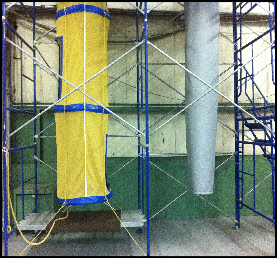

Vertical Kevlar netted Zigzag style Escape Chute

with stainless steel retaining bands:

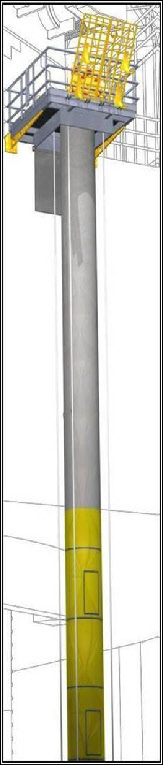

Single layered Netted Kevlar constructed vertical escape chute, the chute is supplied as a continuous chute with stainless steel bands sewn into each 4ft section.

Each section has a Kevlar slide; these are opposing on each section and provide a zigzag effect. At the rear of each zigzag is an exit hatch designed to allow evacuees to exit through any section.

Each 4ft section has a qty of 4 x 4500Ib Kevlar ropes; these provide additional support for each section and the overall chute column. Each section is interconnected with stainless steel connectors providing additional strength. The netted chute has a dead weight capacity of 2 ton.

Each 4ft section has a side compartment for egress and provides the required adjustable height evacuation point. This chute is designed to operate at varying heights for vessels with changes in ballast levels or locations prone to high wave conditions.

Vertical Three Layered Escape Chute:

Three way Protection—The escape chute consists of three layers. The outer layer is of a material that will not ignite. The middle layer helps to regulate the speed of decent, inner layer reduces friction.

Layer 1-

Layer 2: The Middle Layer -

Layer 3: The Inner Layer -

Just sit on the edge, with your legs in the chute and feel it grip you. Slide forward and lower yourself to waist level , spread your legs, and slowly lower yourself fully into the chute. By applying and releasing pressure against the interior wall of the chute, with your arms and legs, You control the speed of decent.